Pre Insulated Pipe Manufacturer in Malaysia

Allied Group is the leading manufacturer of pre-insulated pipe systems in Malaysia, engineered for high-efficiency District Cooling Systems (DCS), HVAC chilled water, and industrial steam applications. Our "Super Power" Pre-Insulated Pipe feature a factory-applied rigid Polyurethane (PU) Foam core protected by a seamless High-Density Polyethylene (HDPE) or Galvanized Steel jacket.

High-Performance PU Foam Insulation for District Cooling & HVAC

Adaptable to Different Design Conditions:

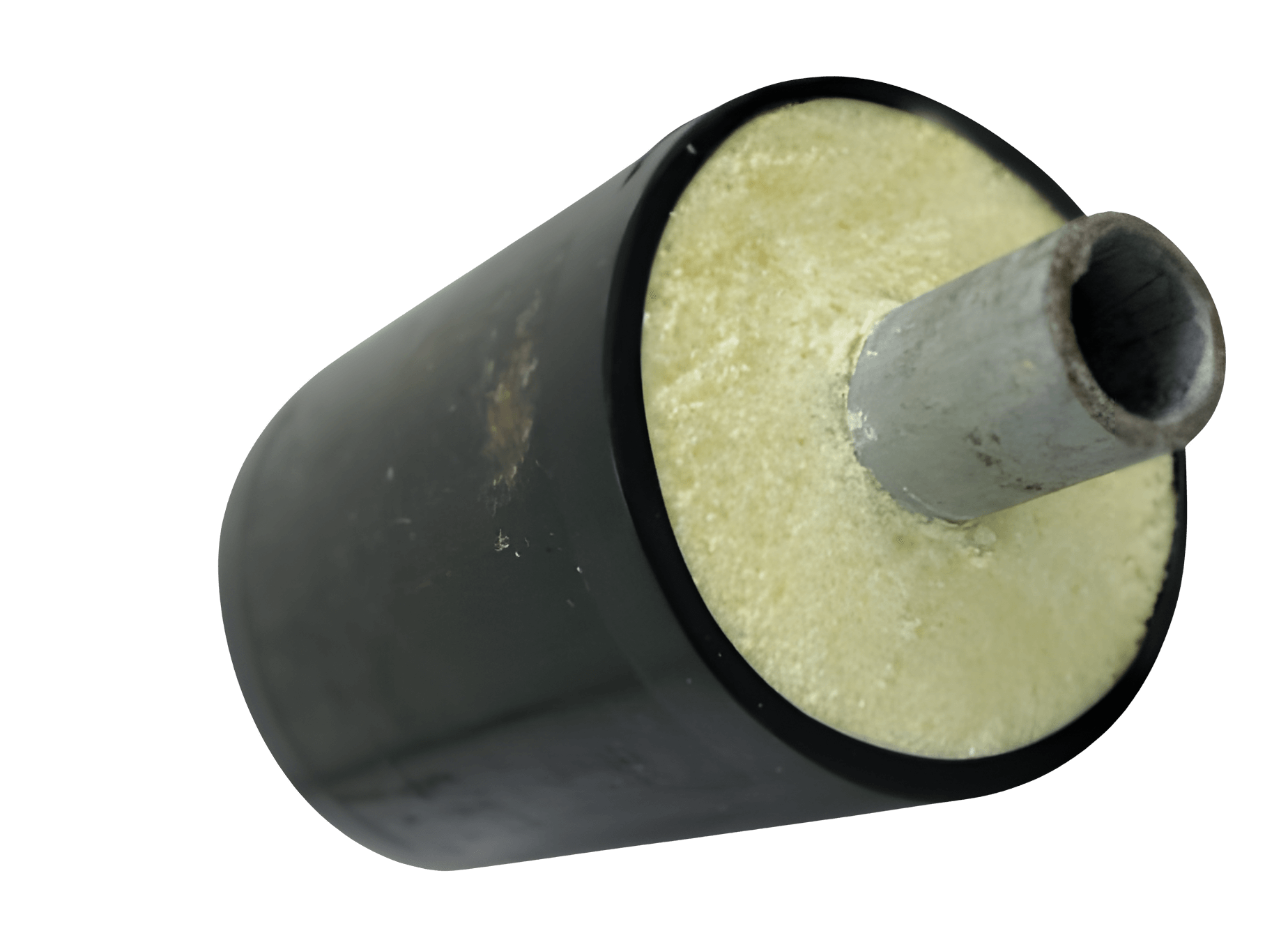

Allied Foam’s “Super-Power” Pre-insulated Pipe mainly consists of three essential elements: the Carrier Pipe, Jacketing, and Insulation. Different selections and specifications can be made to meet specific designer requirements. “Super-Power” Pipe is ideal for Chilled Water Systems, Hot Water Systems, Refrigerant Systems, and Cold Room applications.

Optional Peripheral Jacketing:

In order to sustain a challenging weather or mere hazard condition such os underground, seaside, below freezing point, corrosive environment etc.), protective casing can be applied to “Super-Power ” Pipe. Variances of jacket casing material are Galvanised Steel, Stainless Steel, Aluminium, Colour Bonded/Coated Galvanised Steel, High Density Polyethylene (HDPE), Plastic material and etc.

Higher Insulation Performance:

As compared to other insulation available in the industry. “Super-Power” Pipe has lower thermal conductivity K Value vice versa higher insulation performance. Due to Polyurethane foam like perming chemical reaction, it forms a strong adhesive bond to the pipe’s surface resulting a firm and dense insulation enveloping the pipe.

Why Engineers Choose Our "Super Power" Pre Insulated Pipe

Specially factory-fabricated for rapid installation. The “Super Power” system reduces in situ insulation labor time, ensuring faster project completion.

Prefabricated design eliminates manual lagging. The compact footprint lowers trenching costs and maintenance expenses, making it a high-ROI solution for district cooling.

We manufacture custom density and material combinations (Carbon Steel, Stainless, HDPE) to meet specific designer requirements and thermal targets for any project.

High-density rigid PU Foam (≥48kg/m³) provides superior insulation, securing energy conveyance and minimizing thermal loss along the pipeline.

A seamless HDPE outer jacket protects the core pipe from moisture, corrosion, and physical damage, ensuring a long lifespan in underground conditions.

Stringent ISO quality control systems at our fabrication plant ensure consistent foam density and zero-defect delivery for critical infrastructure.

Why Choose Us

We Are Direct factory manufacturing of high-density PU pre insulated pipes for district cooling and industrial applications.

Based in Balakong, Selangor.

Our Pipe Variant

Engineered Pre-Insulated Solutions for Every Application

- Core: Steel (Black/GI)

- Jacket: Galvanized Steel

- Density: ±45 kg/m³

- Ref: Catalogue Pg 11

- Core: Steel (Black/GI)

- Jacket: Seamless HDPE

- Density: ±50 kg/m³ (Heavy)

- Ref: Catalogue Pg 12

- Core: Copper (BS EN 1057)

- Temp: Up to 65°C

- Jacket: Galvanized Steel

- Ref: Catalogue Pg 13

- Core: Copper (ASTM B88)

- Temp: Down to -5°C

- Jacket: Galvanized Steel

- Ref: Catalogue Pg 14

- Core: Copper Pair Coil

- Temp: -50°C to +20°C

- Jacket: Galvanized Steel

- Ref: Catalogue Pg 15

Polyurethane Technical Data

Foam Density & Thermal Conductivity Specifications

| Properties | Test Standard | Unit | Value | ||||

|---|---|---|---|---|---|---|---|

| CORE DENSITY | ASTM D1622 | KG/m³ | 45 | 50 | 60 | 70 | 80 |

| THERMAL CONDUCTIVITY | ASTM C518 | W/m K | 0.021 | 0.021 | 0.021 | 0.023 | 0.024 |

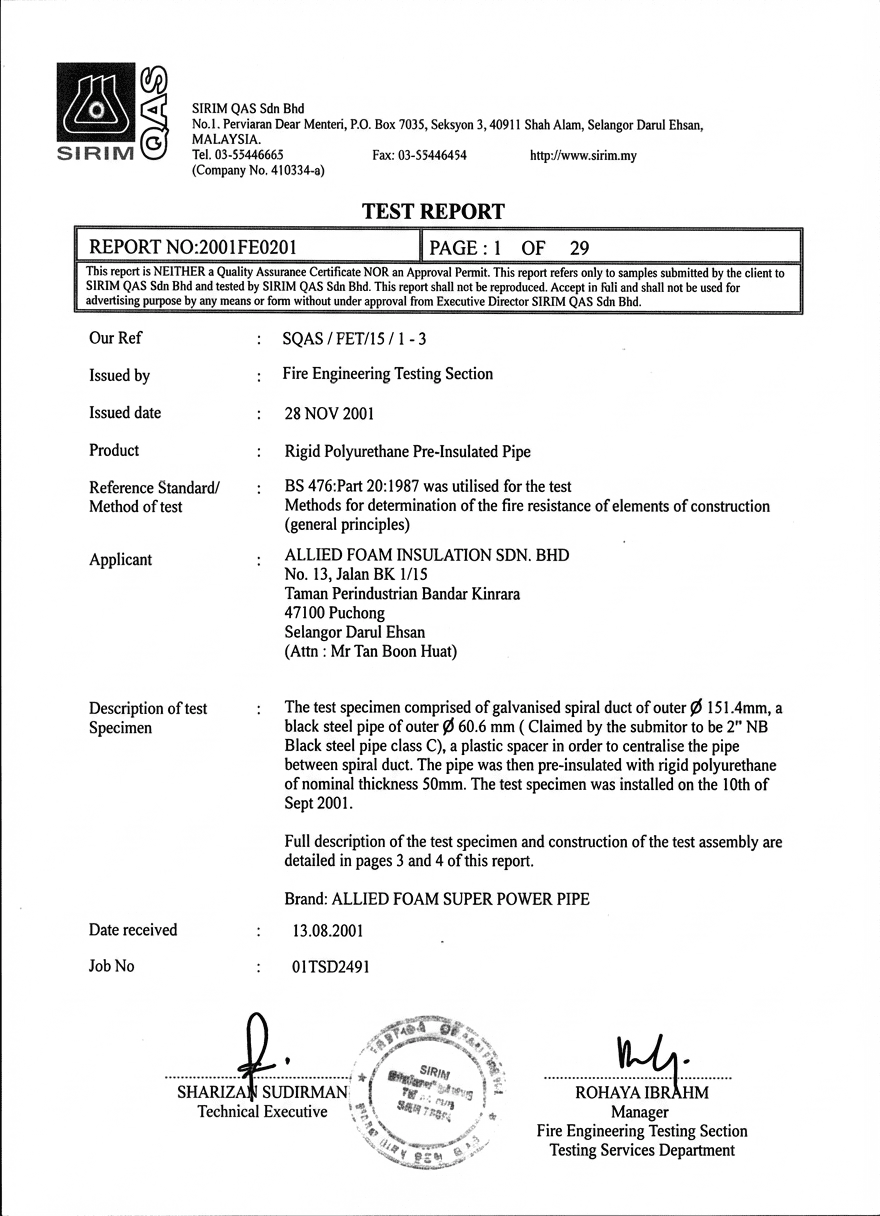

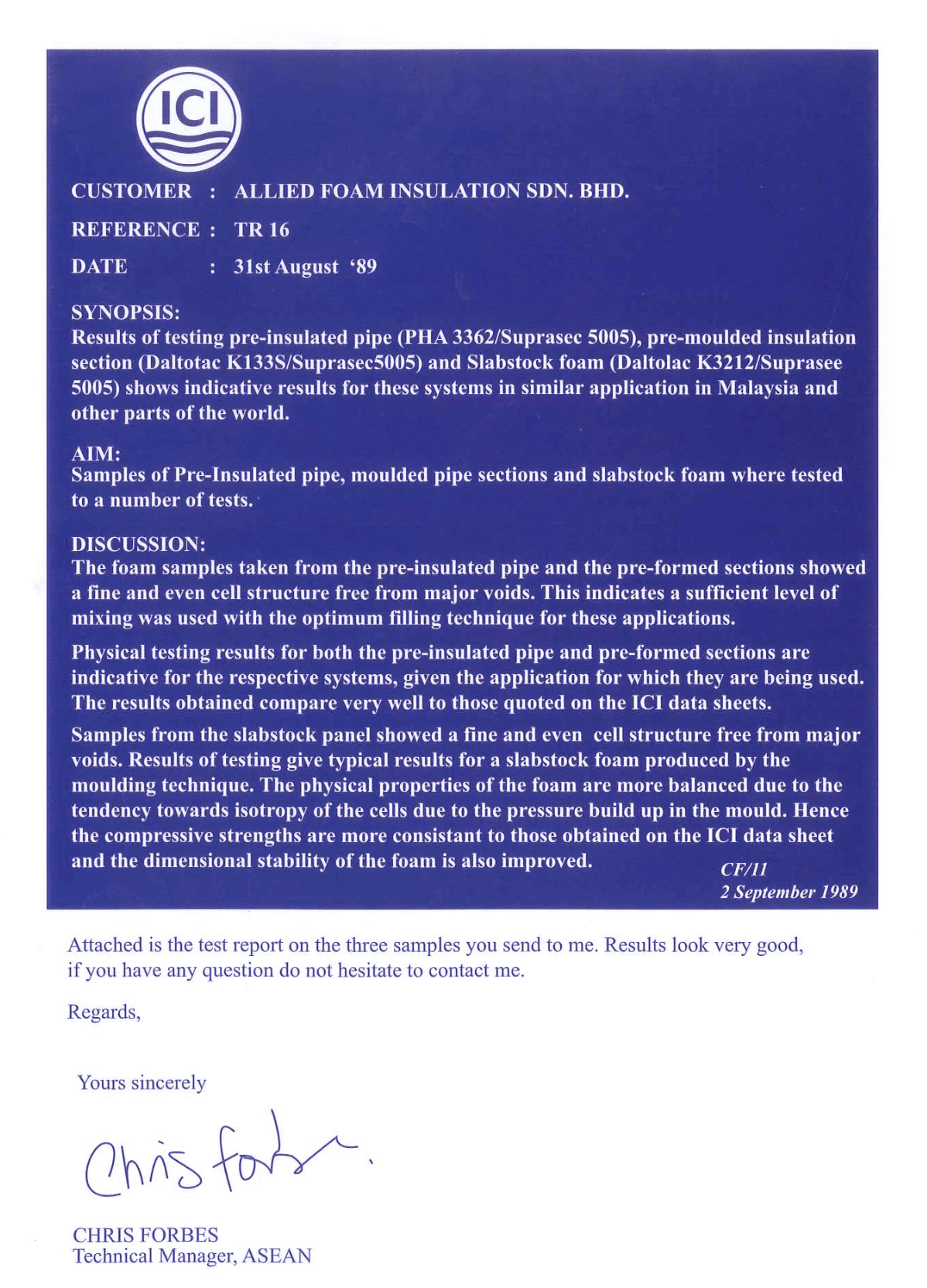

Verified Safety Standards

"Super Power" Pre-Insulated Piping Systems are strictly tested by SIRIM QAS and Warrington Fire Research to meet global fire safety benchmarks.

Project References

Trusted by Icons

Our piping systems are the silent backbone of Malaysia’s most critical infrastructure, commercial hubs, and national landmarks.

KLCC (Petronas Twin Towers)

Kuala Lumpur City CentreKL Tower (Menara KL)

Kuala LumpurPerdana Putra

Prime Minister's Office, PutrajayaParliament of Malaysia

Kuala LumpurKLIA International Airport

SepangInstitut Jantung Negara (IJN)

National Heart InstituteMalaysia Embassy

Phnom Penh, CambodiaGeneral Hospital KL

Kuala LumpurThe Exchange TRX

Tun Razak ExchangeMid Valley South Tower

Mid Valley CityIOI City Mall

Putrajaya (Largest Mall in MY)Sunway Velocity Mall

Cheras, KLIntel Technology

Penang / Kulim PlantsPMO Complex (Brunei)

Brunei DarussalamSunway Putra Hotel

Kuala Lumpur

CATALOGUE ACCESS

This catalogue is password protected.

Please contact sales to obtain the code.

Incorrect password. Please try again.

Frequently Asked Questions about Pre-Insulated Pipe

What is a Pre Insulated Pipe used for? A Pre Insulated Pipe is designed to maintain the temperature of fluids in District Cooling Systems (DCS). Our Pre Insulated Pipe uses high-density Polyurethane (PU) foam to prevent energy loss in chilled water networks.

Do you manufacture Pre Insulated Pipe in Malaysia? Yes, Allied Group is a direct factory manufacturer of Pre Insulated Pipe based in Balakong, Malaysia. We supply Pre Insulated Pipe to major projects like KLCC and TRX.

Is your Pre Insulated Pipe JKR Approved? Yes, our “Super Power” Pre-Insulated Pipe is fully certified by SIRIM QAS and JKR for government infrastructure projects.

How do I get a quote for Pre Insulated Pipe? Click the contact button above to get a direct factory price for your Pre Insulated Pipe requirements.