Super Power Pre-Insulated Piping System

Adaptable to different design condition:

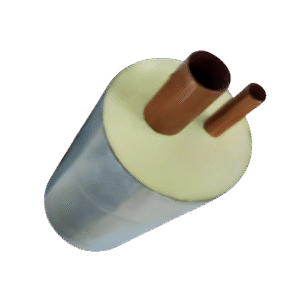

Allied Foam’s “Super-Power ” Pre-insulated Pipe mainly consists of three essential elements which are Carrier Pipe, Jacketing and Insulation. Different selections and specification can be made to meet designer’s requirement. “Super-Power ” Pipe can be applied to Chilled Water/Hot Water System, Refrigerant System, Cold Room Condition & etc.

Optional Peripheral Jacketing:

In order to sustain a challenging weather or mere hazard condition such os underground, seaside, below freezing point, corrosive environment etc.), protective casing can be applied to “Super-Power ” Pipe. Variances of jacket casing material are Galvanised Steel, Stainless Steel, Aluminium, Colour Bonded/Coated Galvanised Steel, High Density Polyethylene (HDPE), Plastic material and etc.

Higher Insulation Performance:

As compared to other insulation available in the industry. “Super-Power” Pipe has lower thermal conductivity K Value vice versa higher insulation performance. Due to Polyurethane foam like perming chemical reaction, it forms a strong adhesive bond to the pipe’s surface resulting a firm and dense insulation enveloping the pipe.

Why Choose Us:

- Ease of Installation : Specially designed and factory fabricated for easy and speed installation to save time, labour and cost.

- Economy : Prefabricated and preinsulated, "Super Power" Pipe are easy to install and thus are very cost effective products

- Flexibility : Different combination of materials can be selected to meet designer's requirement.

- Energy Saving : Better insulation performance securing energy conveying along the pipe.

- Durability : Protective jacketing enable "Super-Power" Pipe to last longer.

- Quality Assurance : Stringent ISO quality control system adapted in fabrication plant to maintain consistently high quality.

- Aesthetic and Space Saving : Less insulation thickness to achieve performance and cleaner outlook, sultable for indoor installation with challenging space constraint and interior design.

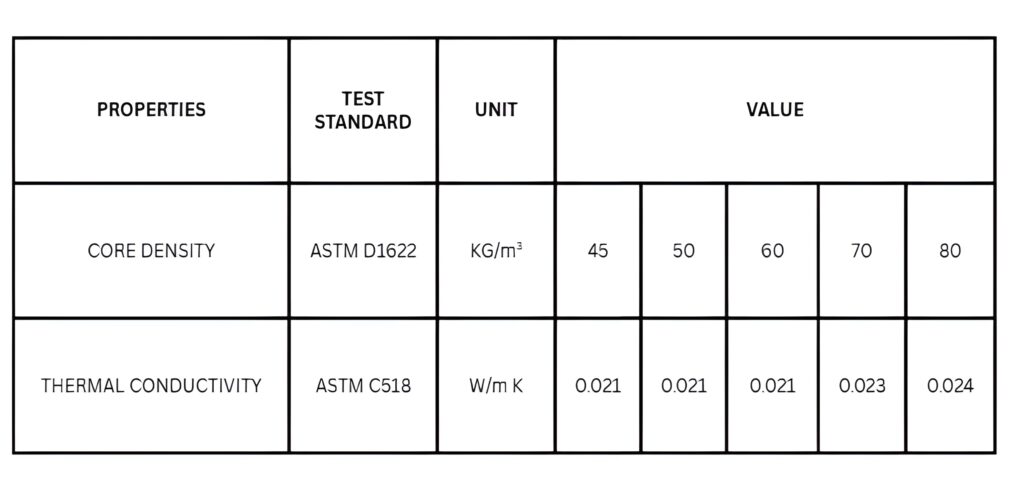

Polyurethane Technical Data:

Allied Foam CFC Free Insulation Data:

Pre-insulated pipe shall be rigid polyurethane & completely fill in annular space between carrier pipe end outer jacket.

The following table contains the typical foam physical properties of FCF free PU system and tested under respective ASTM and ISO standard.

Pre-insulated pipe shall be rigid polyurethane & completely fill in annular space between carrier pipe end outer jacket.

The following table contains the typical foam physical properties of FCF free PU system and tested under respective ASTM and ISO standard.

Please enter the password to get the latest product catalogue.